Williamson Advanced technologies and capabilities of the infrared thermometer:

The manufacturers of the world's only patented - in any industry can be found in the applicable aircraft

Advanced ESP filters

- System status information to provide useful information for operation verification.

- The five measured parameters, the thermometer can effectively describe a wide range of conditions (see table below). Each measurement parameters can be seen on the thermometer display, or sent to other parts of the programmable output and alarm.

- Pre-programming, application-specific ESP mode automatically recognize and compensate for wide range of application conditions. ESP parameters, can be easily adjusted for customer application needs or fine tune existing ESP mode.

- A text-based menu, you can easily view and adjust the system parameters. If you need to be adjusted, there is no manual or special training needs to translate the arcane programming code.

- The thermometer can "turn off", and displays status messages that ESP filter is out of range.

- The peak hold function can display and maintain the final effective temperature measured value before the occurrence of an invalid.

PRO Series tradition of innovative design of the dual multi-wavelength sensors ESP filter and difficult applications

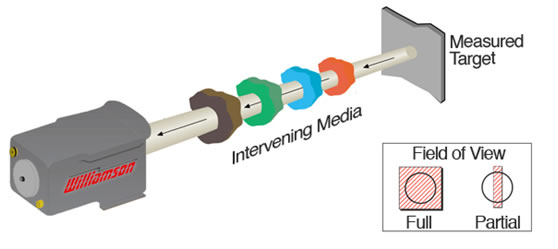

The infrared thermometer uses an optical system to collect the infrared energy to measure the target area. This energy is used to calculate the target surface temperature. In many industrial and laboratory settings, there is often interference thermometer amount of infrared energy collected, including: radiation rate of change, dislocation, and to intervene in the optical obstructions and stray reflected infrared energy application problems.

PRO Series dual-wavelength and multi-wavelength pyrometer ESP to improve and simplify the management of these applications. ESP, which means that the "aim and read the even the most demanding applications.The unique function of the ESP include:

All the combination of these innovative features, so that the temperature of the PRO Series dual-wavelength and multi-wavelength meter is better than the traditional non-contact temperature thermometer, and is the most simple applications.

ESP filtering in the presence of serious interference to ensure the validity of measurement, this is not always possible to eliminate sources of interference. Williamson's unique ESP filter the signal strength and signal dilution, it is possible to overcome the interference of long-lasting application.

PRO Series dual-wavelength and multi-wavelength pyrometer continuously measuring the signal strength and signal dilution. Each application has the characteristics of acceptable values ??for these parameters, these measurements the thermometer provided valuable information on the application of conditions.

ESP filter to do it by setting the dilution of signal strength and signal applications are characterized by the scope of the thermometer can automatically identify valid and invalid conditions, and respond appropriately. ESP filter can be pre-programmed for specific applications and the site is easy to adjust the text-based menu program for unique applications and ad hoc failure to exclude

There are two possible responses, the thermometer can provide an invalid operating conditions:

The final results of the ESP filter, the thermometer will display only the temperature but also accurate and reliable. ESP filters enable more reliable temperature monitoring to help improve process quality control and productivity.

An example of using the ESP filter, to ensure effective reading of the temperature measurement of molten iron flow. In this application, smoke, sparks and reflection often makes the measurements extremely difficult. Three figure illustrates how to make advanced ESP filter used to identify the conditions change, so that the thermometer to reflect more accurate and reliable temperature measurement.

Advanced dual-wavelength design

- Intervention of the media, such as smoke, steam, dust, spray, particulate matter, or dirty windows, or mechanical disturbances, light attenuation.

- Part of vision caused by the mechanical barrier and the small drift of the target. The thermometer has the ability to signal dilution factor to compensate for the interference of these types of applications. Signal dilution factor expressed as a ratio, on behalf of the extent of the signal is diluted, a thermometer can be tolerated, while also providing an accurate temperature readings. For example, a 500:1 signal dilution factor, the thermometer has more than 500 times the infrared signal is compared to a measurement requirement is even higher. Higher signal dilution factor, the thermometer is more able to tolerate the application of interference.

- Williamson PRO 81/91 - 110/210 Thermometer:1500:1

- Williamson PRO 82/92 - 120/220 Thermometer:500:1

- Competitive two-color pyrometer:100:1

- Improve accuracy and reduce maintenance in the harsh environment, the energy of the target was interference by the middle of the media by dilution.

- Without precise alignment, when the analyte target is small or will drift. PRO Series dual-wavelength and multi-wavelength pyrometer signal dilution value is displayed as one of the five measured parameters in order to provide a 'live' thermometer signal verification of the dilution factor.

- Aluminium

- Chromium

- Copper

- Molybdenum

- Stainless steel

- Titanium

- Tin

- Tungsten

- Zinc

The infrared thermometer using an optical system to collect the infrared energy to measure the target area. This energy is used to calculate the target surface temperature. In many industrial and laboratory environments, it is often a lot of energy interference is collected by the thermometer application

These applications include:

The typical maximum signal dilution

PRO Series dual-wavelength and multi-wavelength pyrometer provides a high signal dilution factor has the following benefits in the harsh application conditions.

Advanced ESP multi-wavelength filter design

Correction using the irregular changes of the emission rate ESP calculus

Successful non-ash material temperature measurement is difficult because of the complex radiation rate changes occurred in the surface oxidation of the alloy composition, surface texture, temperature or crystal structure. In addition to the highly controlled conditions, the traditional single wavelength and dual wavelength pyrometer can not compensate for these changes.

Williamson's unique multi-wavelength infrared thermometer to use the advanced ESP algorithm to solve this complex problem. ESP algorithm is based on the experience of computer-based model to consider the infrared energy, emissivity, and the measurement wavelength, the appropriate compensation in the non-ash material irregularity.

The following figure illustrates the accuracy of the multi-wavelength pyrometer in a typical non-gray body materials, stainless steel. By using stainless steel algorithm to compensate for changes in the rate of radiation, multi-wavelength pyrometer provides excellent results, which means that the "ability to target and read". Williamson has developed a multiple application-specific ESP filter to compare the results with previously to consider the difficulties to the measurement application.

Examples of non-gray material:

Each multi-wavelength pyrometer up contains four menu options, factory-programmed ESP algorithms and measurement of dual-wavelength dual / ratio mode. This is also very easy to build advanced ESP model combining ESP ESP filter algorithm under adverse operating conditions, measurement of non-ash material can measure.

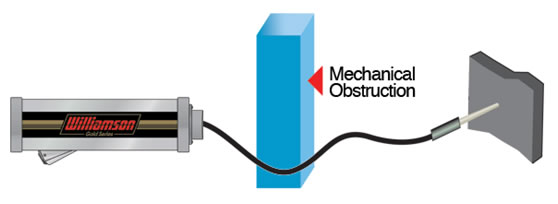

Fiber optic

- ArmorGuard (AG) system - heavy-duty, flexible, two layers of stainless steel armored fiber insulation and air purification in order to prevent flame impingement and high ambient temperature under the protection of fiber optic cable pipeline.

- Braided stainless steel system (SSB) - long-lasting internal Teflon casing and general industrial facilities protection, air purification, a flexible, lightweight fiber optic cable pipeline.

- Monofilament fiber cables (MN) - PTFE jacket and Teflon coat. Provide them with a smaller diameter of 0.05in, 1.3 m and the non-conductive packaging. For very small space and a useless high potential for electromagnetic interference is the ideal choice.

The Fibre thermometer using a small sealed fiber-optic cable to view the target temperature measurement meter installed on the remote or more convenient location. This provides greater durability and flexibility of the sensor device, and involving a confined space or in harsh environments. Cable length from 3-30 feet (1-9 meters) range. In addition to standard fiber-optic cable Williamson provided the following options: