Rotary kiln / Rotary drying oven

A variety of production dry sludge / sludge soil mercury and solvent desorption / sintering rotary kiln

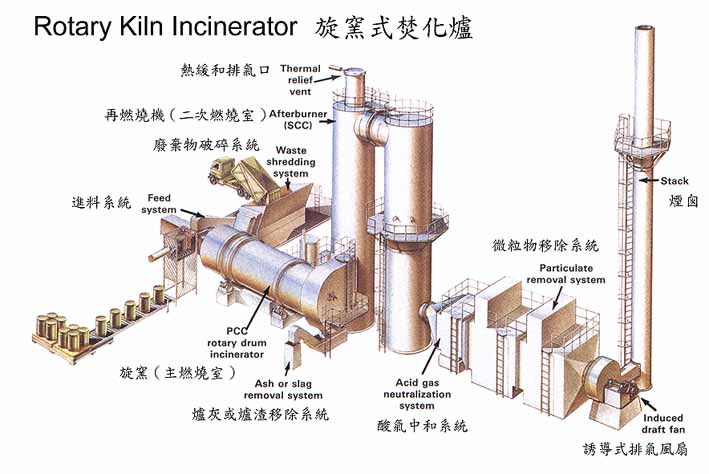

Rotary kiln incinerator - currently in the solid or liquid waste treatment technology development, the most universal and progress of the incinerator system

View within the rotary kiln: on the left into the entrance and exit, the upper right of the main burner, the bottom right of the waste jet gas turbine, the kiln has four implanted furnace Jan wing, are available to turn the lift solid increase in the heat furnacegas contact with the function

The great flame within the main burner in the rotary kiln

Rotary kiln waste spray the flames in the gas turbine

Powder rotary calcination furnace

Calcined temperature: Max.1080℃

Heat treatment:300~400 kg/h

(Heat treatment capacity according to customer demand for custom design)

Calcined material:MnZn Material

Speed:2 ~ 6 RPM

Diameter: 600 mm

Heating zone control:Area 3

Heating zone length:7000 mm

Heating method:indirect heating tube

Cooling zone length:2500 mm

Cooling method:tube external water cooling

Fuel:Gas

Combustion control:pulse combustion control

The installation site:

- Device number: 2 sets

Soil decontamination rotary furnace equipment

Calcined temperature: Max.800℃

Heat treatment:5000 kg/h

(Heat treatment capacity according to customer demand for custom design)

Calcined material:Pesticide-contaminated soil

Speed:2 ~ 10 RPM

Diameter: 1000 mm

Heating zone length:12000 mm

Heating method:direct heating

Fuels:Heavy oil

Follow-up treatment:1000 ° C the second exhaust gas incinerator, water scrubber and dust collection equipment

The installation site:

達闊環境工程有限公司

Oxides and chemical raw material rotation (fire above) burning stove / sludge soil mercury and solvent desorption rotary kiln

Calcined temperature: 550℃, Max: 700℃

Heat treatment:10,000 kg/8h

(Heat treatment capacity according to customer demand for custom design)

Calcined material:Oxides

Speed:2 ~ 6 RPM

Diameter:650 mm/800 mm

Heating zone length:20,000 mm/12,000 mm

Heating method:direct heating

Fuels:Gas / Diesel

Material residence time: 1~2 hr

Heating zone control:Area 4/12 burner

Combustion control:pulse combustion control

The installation site:

Taiwan / Taichung 06.OCT.2008

Taiwan / the Yunlin 21.JUL.2011

Typical customer:

- Device number:2 sets

- Device number:1 set

化工

金友科技